Wednesday, 26 October 2011

Hamilton By Design: 3D Design Services - Solidworks

Friday, 21 October 2011

Hamilton By Design: Hamilton By Design the Design Team

Hamilton By Design: Hamilton By Design the Design Team

Hamilton By Design the Design Team

The goals of the individuals involved must be in sync with the group’s goals. Different intended outcomes will lead to failure. Each team member has a shared understanding of the design process, where the design team has a common framework and shared language for working together.

Hamilton By Design offer effective collaboration between all stakeholders thus requires each to commitment to shared methodology, terminology, and milestones. Our process includes open critiques with all members participating—the goal is to identify and develop the very best ideas from all of our talented sources.

www.hamiltonbydesign.com

Monday, 2 May 2011

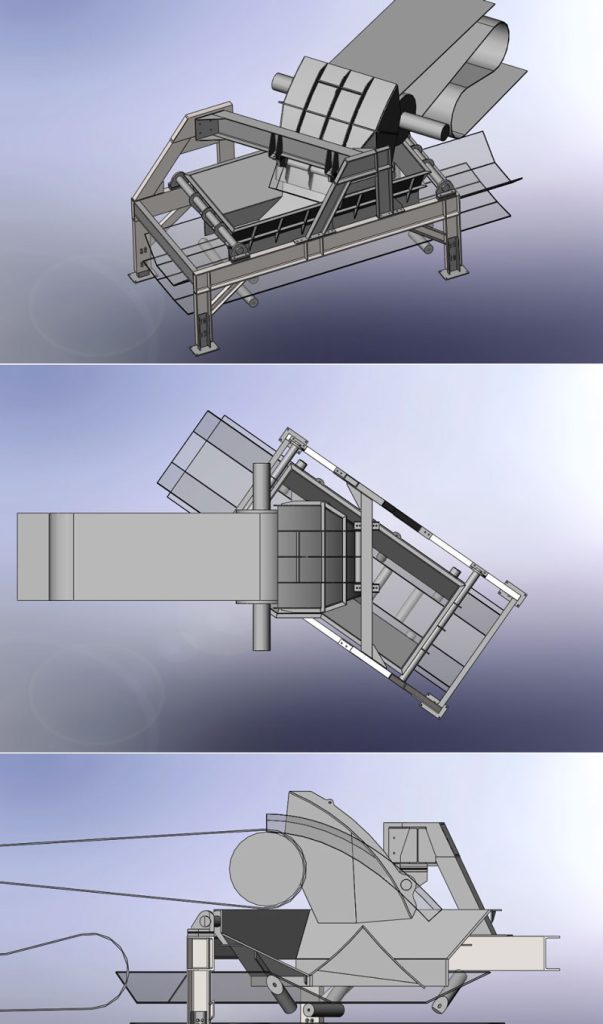

Solidworks Designers

For quality designs that are certain to go together contact Hamilton By Design today

(02) 4325 3519.

Thursday, 28 April 2011

Solidworks Designers

Anthony Hamilton

www.hamiltonbydesign.com

Software and Systems

Provide data in the following formats:

Using the following software:

We rely on on our software preforming complex tasks in a seamless fashion from an operators prospective as a supplier to clients we strive to offer the same level of service.

Hamilton By Design

Hamilton by Design -- Finite Element Analysis

Fabrication Shop Drawings

Structural Detailing

Offer a service of producing fully detailed fabrication shop drawings in many cases these fabrication drawings take the shape of detailed assemblies. Each drawing offers enough information to enable a fabricator to produce along with check details of a fabrication prior to erection of an engineers / architects vision. The process at Hamilton by Design Structural Detailing is one of open communication by molding an intellectual vision or dream into a shop drawing format which is easily cross check able references. These references or data points drive a three dimensional solid model complete with interference detection in turn produce fabrication cutting lists in conjunction with bills of materials are produced prior to detailing of fabrications and or individual components if required.

Hamilton by Design Structural Detailing have experience including yet not limited to producing fully detailed drawings such as, Factory layouts, Structural layouts, Cutting schedules, Cutting profiles, Keyed plate structures many of these have produced projects like, Portal Frames, Mezzanine Floors, Multi storey Frames, Large Span Truss Frames, Erection Supports, Steel frames, Machine Structures, Lifting Frames, Lifting Crabs, Lifting Rails, Raw materials milling machines, Raw materials grinding machines, Raw material cyclones, Steel making Vessel, Blast Furnace structures, Coal washery infrastructure, Materials conveying and transfer systems, Mining Infrastructure, Piping layouts, Industrial Stairs, Ladders, Canopies, Artistic Architectural Steelwork, Large Automatic Gates.

Additional information on Hamilton by Design Structural Detailing can be found at

Tuesday, 19 April 2011

Tooled Up with MCAD

Mechanical

Engineering | Structural

Engineering

Mechanical Drafting

| Structural

Drafting

3D CAD Modelling | 3D Scanning

Hamilton By Design

Monday, 11 April 2011

Central Coast Toolmakers - Gosford

Australia Made and Australia Proud.

Web Site

www.alnoproductservices.com.au

Blog Page

Gosford Solidworks 3D Modlelling Contractors

Solidworks 3D Modlelling Contractors

SolidWorks 3D Modelling Contractors – Engineering Support That Works

Back in 2011, SolidWorks was already one of the world’s most popular 3D modelling tools for engineers and designers. Today, it remains a cornerstone of modern mechanical design, fabrication workflows, and product development — and the demand for experienced SolidWorks contractors has only grown.

If your business needs reliable SolidWorks support, whether for short-term work or ongoing engagement, the right contractor can make all the difference.

Why SolidWorks Still Matters

SolidWorks is more than just a 3D CAD package — it’s a design and engineering backbone used in:

machine design

product development

sheet metal fabrication

assemblies and mechanisms

plant layouts and spatial coordination

reverse engineering workflows

Good 3D models aren’t just pretty — they’re the source of drawings, analyses, and fabrication data.

Beyond Software — Engineering Experience Counts

There are plenty of people who “know how to run SolidWorks.” But what makes a contractor valuable is how they apply SolidWorks to real engineering problems — not just how fast they can sketch geometry.

Experienced SolidWorks contractors understand:

✔ design intent

✔ manufacturability

✔ assembly logic

✔ tolerance control

✔ CAD standards

✔ documentation quality

This leads to models and drawings that actually support engineering teams, fabricators, and project stakeholders.

If you’re outsourcing CAD work, aim for someone who understands both the tool and the engineering outcomes it’s meant to support.

When to Engage SolidWorks Contractors

Companies often call on contractor support because:

internal design teams are overloaded

projects have unique or complex geometry

deadlines are tight and flexibility is needed

legacy products need updating in CAD

models must be converted to manufacturing data

simulation, analysis, or documentation is required

Rather than slowing down due to capacity or capability constraints, a SolidWorks contractor can help you stay on schedule with quality you can rely on.

How Hamilton By Design Supports You

At Hamilton By Design, we specialise in SolidWorks engineering services tailored for real projects — not just textbook CAD exercises.

From concept modelling to manufacturing documentation, our services include:

parametric 3D modelling

assembly creation and interference checking

sheet metal unfolding and DXF exports

detail and fabrication drawings

scan-to-CAD and as-built workflows

model optimisation for CNC, fabrication, or FEA

We deliver CAD outputs that integrate cleanly with your existing workflow and standards.

SolidWorks Contractors in Australia

If you’re seeking experienced SolidWorks contractors in Australia, we can assist you with:

This page explains how we support engineering teams across Australia with flexible, reliable, and skilled SolidWorks contract support — for short or long term projects.

Learn More About Our SolidWorks Services

For a deeper overview of our SolidWorks capabilities, including design, documentation, and engineering support, visit:

📌 https://www.hamiltonbydesign.com.au/home/engineering-services/solidworks/

That page outlines our approach, tools, and how SolidWorks fits into broader engineering workflows.

Final Thought

SolidWorks has stood the test of time because it’s powerful, flexible, and widely adopted across industries. But its value truly shines when it’s used by people who understand both the software and the engineering outcomes it must deliver.

Whether you need short-term contract support or long-term modelling expertise, working with experienced SolidWorks professionals will help you turn ideas into engineerable and manufacturable reality.

👉 Explore both our SolidWorks service overview and contractor support pages — and make your next project smoother and more predictable.

3D Design Services - Solidwor...

Hamilton By Design – Engineering Support from Gosford to Sydney

This post was originally written in 2011, when CAD and drafting services were already playing an important role in engineering and manufacturing.

Since then, the tools have evolved — but the need for clear, accurate engineering documentation has only increased.

At Hamilton By Design, we continue to support clients across Gosford, the Central Coast, and Sydney with engineering-focused design and drafting services that help projects move from idea to build with confidence.

From CAD drafting to digital engineering

Back when this was first written, most projects started with drawings or basic 3D models.

Today, many projects start with:

-

existing sites and assets

-

brownfield environments

-

incomplete or outdated documentation

Modern engineering now combines traditional drafting skills with 3D modelling, reality capture, and scan-to-CAD workflows to reflect what actually exists — not what we assume exists.

The goal remains the same:

produce documentation that people can build from.

Why drafting and design still matter

No matter how advanced software becomes, good outcomes still rely on:

-

clear drawings

-

correct dimensions and tolerances

-

well-structured models

-

documentation that fabricators and installers trust

Poor documentation leads to rework, delays, and unnecessary cost.

Good documentation saves time, money, and frustration.

That hasn’t changed since 2011 — it’s just become more important.

Supporting real projects, not just drawings

Hamilton By Design has always focused on practical engineering support, not just CAD output.

That means helping clients with:

-

drafting for fabrication and installation

-

design development and refinement

-

as-built documentation

-

upgrades and retrofit projects

-

converting site conditions into reliable drawings

Whether the job involves mechanical equipment, structures, fit-outs, or existing facilities, the aim is the same: accuracy and clarity.

Modern tools, same engineering mindset

While the tools have advanced — including 3D scanning, LiDAR, and digital modelling — the mindset remains engineering-led.

Today’s workflows allow:

-

faster capture of existing conditions

-

better coordination between disciplines

-

fewer assumptions during design

-

improved confidence before fabrication

These tools don’t replace drafting — they strengthen it.

Working across Gosford, the Central Coast & Sydney

From its beginnings on the Central Coast to ongoing work across Sydney and beyond, Hamilton By Design continues to support businesses that value:

-

practical engineering input

-

clear communication

-

documentation that works on site

Some projects are small and focused. Others evolve over time.

Both benefit from dependable drafting and design support.

Moving forward

Looking back at this post from 2011 highlights how much has changed — and how much hasn’t.

Good engineering still depends on:

understanding real-world constraints

communicating design intent clearly

delivering documentation that supports construction and fabrication

That’s what Hamilton By Design continues to focus on today.

If you’re reviewing older drawings, planning an upgrade, or starting a new project, modern drafting and design workflows can make a significant difference — especially when they’re backed by engineering experience.

3D Design Services - Solidworks

Hamilton By Design – 3D Design Services You Can Rely On

In today’s engineering and fabrication environment, good design isn’t optional — it’s essential.

Whether you’re developing a new product, engineering a custom solution, or turning concepts into buildable reality, having a dependable 3D design partner can make all the difference.

At Hamilton By Design, we provide comprehensive 3D design services tailored to support businesses that need real-world results — not just pretty pictures.

Why 3D Design Matters

3D CAD design is the foundation for everything that follows in a project:

accurate drawings

efficient fabrication

clash detection and interference checking

clearer communication between teams

better cost estimating

When 3D design is done right, the entire project benefits.

Our Approach to 3D Design

We combine technical detail with practical engineering experience to deliver 3D models that are useful, accurate, and built for purpose.

Our 3D design services include:

parametric modelling for rapid design changes

assemblies with interference checking

production-ready CAD for manufacturing

sketching and concept modelling

reverse engineering from scans or existing parts

Whether you’re working with sheet metal, structural framing, mechanical systems, or plant layouts, we deliver 3D design you can build from.

Tools and Platforms

We use industry-standard tools to ensure compatibility with your projects, software, and fabrication partners. Our experience spans multiple CAD platforms, focused on producing design outputs that integrate seamlessly into:

manufacturing workflows

fabrication drawings

CNC and automated processes

simulation and analysis

Your models aren’t just 3D — they’re engineered to be useful.

When to Engage 3D Design Services

Clients come to us in many situations, including:

overloaded internal design teams

complex geometry that needs professional modelling

models that need manufacturing documentation

designs pulled from conceptual sketches

scan-to-CAD workflows from reality capture

If you need design confidence, better documentation, or more reliable outputs, professional 3D design support can be a game changer.

Trusted Design Support

At Hamilton By Design, we understand that good design is more than just technical. It’s about communication, clarity, and deliverables that support your project goals.

We work with:

engineers who need extra capacity

project teams looking for dependable models

fabricators needing manufacturing-ready data

clients with legacy assets that need digital representation

What unites them all is the need for accurate, buildable design work.

Learn More About Our 3D Design Services

If you’re planning an engineering, fabrication, or construction project and want dependable 3D design support and outcomes, we can help.

Explore our 3D design capabilities here:

https://www.hamiltonbydesign.com.au/home/engineering-services/3d-design/

This service page explains:

how we approach 3D design work

when it makes sense to bring the experts in

how good design drives better project outcomes

A Final Thought

Great outcomes start with great design — especially when the next step is fabrication, installation, or manufacture.

Whether your need is big or small, urgent or planned, professional 3D design support gives you confidence that your project can move forward with clarity and control.

👉 Check out our 3D design services for more detail:

https://www.hamiltonbydesign.com.au/home/engineering-services/3d-design/

Hamilton By Design

Engineering Drafting in Gosford & Sydney – Drawings You Can Build From

If you’ve ever had a fabrication or installation job stall because the drawings weren’t clear, you already know this:

Drafting isn’t just lines on a page — it’s how your project gets built correctly the first time.

At Hamilton By Design, we support clients across Gosford, the Central Coast, and Sydney with engineering-led drafting services that are practical, accurate, and ready for real-world use. Whether you’re fabricating, upgrading, installing, or documenting an existing asset, good drafting removes uncertainty.

Why good drafting pays for itself

Drafting is where design intent becomes something your team and your fabricator can actually use. Quality drafting helps reduce:

• site rework and delays

• missing dimensions or unclear tolerances

• cost blowouts caused by late changes

• shutdown risk when upgrades don’t match existing conditions

When the drawings are right, everything downstream becomes easier.

Drafting that starts with reality: LiDAR and scan-to-drawing

Many projects don’t start with clean drawings. They start with what’s already there — an existing structure, brownfield site, plant area, or legacy equipment with limited documentation.

By using LiDAR scanning and scan-to-CAD workflows, drafting can reflect real conditions rather than assumptions. This allows drawings to accurately capture:

• actual clearances and constraints

• existing steelwork, services, and interfaces

• true as-built conditions

This approach is especially valuable for upgrades, retrofits, shutdown planning, and fit-first-time fabrication.

What we typically deliver

Depending on the project, our drafting services commonly include:

• fabrication and shop drawings

• as-built drawings and documentation sets

• GA drawings and layout plans

• detailed drawings with practical callouts

• revision-ready CAD outputs aligned to your workflow

The goal is always the same — drawings that can be quoted, fabricated, installed, and maintained without guesswork.

Supporting projects across Gosford, the Central Coast & Sydney

We work with local businesses and project teams who need reliable drafting support without the runaround — from one-off drawing packages to ongoing drafting assistance as projects evolve.

If you’re paying for fabrication or construction, investing in quality drafting is one of the highest-return decisions you can make.

Learn more about our drafting services

To see how we approach engineering-led drafting, including LiDAR-supported workflows, visit:

If you’re planning an upgrade, refurbishment, or need drawings that accurately reflect what’s on site, start with the drafting overview above.

Solidworks - Inventor - 3D Modelling Gosford - Sydney

Hamilton By Design – Professional Engineering Drafting & LiDAR Scanning Services

If you’re looking for reliable, accurate engineering drafting services, you’re not alone.

Whether you’re developing a new product, documenting an existing asset, or preparing designs for fabrication, clear and precise drafting is essential. Good drafting doesn’t just represent geometry — it communicates intent, tolerances, and build information in a way that your fabricators and suppliers can trust.

At Hamilton By Design, we specialise in professional drafting services backed by engineering expertise — ensuring the drawings you rely on are accurate, useful, and ready for real-world production.

Why Drafting Still Matters

In a world where 3D models are everywhere, 2D drafting still plays a critical role in engineering and manufacturing.

Detailed drawings are used for:

fabrication and assembly instructions

compliance and certification documentation

quoting and production planning

site installation and coordination

A good draft is more than “lines on a page.” It’s a communication tool between design engineers, fabricators, and builders — and mistakes here cost time and money.

That’s why many businesses choose to work with experienced drafting professionals.

More Than Just Lines — Engineering-Led Drafting

A lot of firms will offer “CAD” or “drafting” as a feature — but drafting that’s supported by engineering intent and understanding is a different level of service.

Our drafting services deliver:

Engineering-ready 2D fabrication drawings

BOM (Bill of Materials) documentation

Tolerances and fitment callouts

Easily readable, compliant documentation

Revision history and version control

We work with clients in sectors where clarity matters — including manufacturing, construction, infrastructure, rail, automotive, and custom fabrication.

LiDAR & Reality Capture — Bringing the Real World Into Your Drawings

Many modern projects start with real-world geometry — whether it’s a brownfield structure, an existing asset, or a legacy machine with no drawings.

In situations like this, traditional drafting can’t be done from memory or rough measurements. That’s where LiDAR and 3D scanning come in.

Once a site or asset is scanned using LiDAR technology, the point cloud data can be used to generate accurate drafting deliverables — and save you time, risk, and rework.

This is especially useful for:

retrofit and upgrade projects

existing plant documentation

reverse engineering

as-built drawings

Trusted Drafting Support for Your Engineering Team

Whether you need help with one-off drawings or ongoing drafting support, we integrate with your workflow to deliver fast, accurate results.

Our drafting support can help you:

free up your internal resources

reduce drafting backlogs

improve drawing quality and consistency

transition from 3D scans to production documentation

We treat your drawings with the same care we would our own — because accuracy is everything.

Get It Right the First Time

Good drafting saves headaches later.

Poor documentation leads to:

❌ miscommunication

❌ rework and delays

❌ cost blowouts

❌ site coordination failures

Good drafting makes your engineering smarter, smoother, and more reliable.

If your next project involves:

fabrication

construction

production

installation

site verification

or asset lifecycle documentation

then expert drafting is one of the best investments you can make.

Learn More About Our Drafting Services

At Hamilton By Design, we specialise in professional engineering drafting and reality capture workflows that help businesses convert ideas into manufacturable documentation.

👉 Find out how we can help here:

https://www.hamiltonbydesign.com.au/home/engineering-services/services-drafting-lidar-scanning/drafting/

Whether you need detailed fabrication drawings, as-built documentation, or scan-to-CAD deliverables, we’ve got you covered.

Final Thought

Drafting is not a commodity. Done right, it drives efficiency, reduces risk, and improves outcomes — in design, manufacture, and construction.

Work with experts who understand both engineering and drafting, and gain the confidence that your documentation says exactly what it needs to say.

👉 Explore our drafting services today.

Wednesday, 2 February 2011

SolidWorks Contractors

Why You Should Engage SolidWorks Contractors for Engineering Success

In today’s competitive engineering landscape, turning ideas into reality quickly and accurately isn’t just a bonus — it’s a necessity. Whether you're refining a prototype, producing detailed manufacturing documentation, or preparing models for fabrication, the right CAD expertise can make all the difference.

That’s where SolidWorks contractors step in.

But not all contractors are the same and getting engineering outcomes you can trust requires more than just clicking buttons — you need experience, discipline, and a partner who understands both design and engineering.

What Makes SolidWorks So Valuable?

SolidWorks is one of the world’s most widely adopted 3D CAD platforms — and for good reason:

Intuitive interface and powerful modelling tools

Parametric design that lets you make changes quickly and confidently

Built-in analysis and drawing generation tools

Seamless compatibility with manufacturing and fabrication workflows

But software alone doesn’t guarantee results.

You need someone who knows how to apply SolidWorks to real engineering problems, not just create pretty pictures.

Why You Might Need a SolidWorks Contractor

Many businesses find themselves in one of these situations:

✅ Tight Project Deadlines

Internal teams are overloaded. You need quality output now, without sacrificing accuracy.

✅ Complex Geometry or New Challenges

Your in-house team hasn’t tackled this type of design before.

✅ Lack of Detailed Engineering Documentation

Good design isn’t just geometry — it’s drawings, tolerances, assembly references, and release notes.

✅ Need for Manufacturing or Fabrication Support

From CNC machining to sheet metal folding, your CAD model needs to behave correctly in the real world.

In all of these cases, a SolidWorks contractor with engineering experience becomes a strategic advantage.

More Than Just CAD — We Engineer Solutions

At its core, SolidWorks is a tool. What makes it powerful is who’s using it and how well they understand engineering intent.

A quality SolidWorks contractor should be able to deliver:

Product and machine design

Assembly modelling and interference checking

Sheet metal unfolding and DXF output

Detail drawings with tolerancing and annotations

Design for manufacturing (DFM) guidance

Revision control and documentation

This isn’t just “draughting” — it’s engineering.

When You Outsource CAD Work, Make It Worthwhile

Outsourcing your SolidWorks needs should elevate your team, not complicate your workflow.

A great contractor will:

✔ Work in your environment and standards

✔ Produce files that slot straight into your PLM/PDM

✔ Communicate clearly with your engineers

✔ Eliminate ambiguity in design intent

✔ Reduce errors, rework and ambiguity

Your engineering output shouldn’t just look good — it should function right the first time.

Trusted SolidWorks Expertise at Hamilton By Design

If you’re looking for more than just somebody “who knows SolidWorks,” look for someone who knows engineering and manufacturing — because that’s the combination that actually delivers results.

At Hamilton By Design, we specialise in SolidWorks engineering services that help companies:

📌 Bring products and machines from concept to production

📌 Optimise geometry for performance and manufacturability

📌 Deliver complete fabrication documentation

📌 Support revisions, assemblies, and integration with fabrication workflows

Whether you need short-term contract support or ongoing CAD engineering expertise, our team can step in seamlessly.

Want Better Results from Your CAD Work?

If you’ve been thinking:

“We need help with SolidWorks modelling”

“Our drawings aren’t detailed enough”

“We need someone who ‘gets’ engineering outcomes”

“We want to release designs faster and with fewer errors”

Then don’t settle for general CAD help — work with engineering professionals.

👉 Learn more about our SolidWorks engineering services here:

https://www.hamiltonbydesign.com.au/home/engineering-services/solidworks/

Let’s turn your ideas into engineered reality — faster, smarter, and with less headache.

Bottom Line

SolidWorks isn’t just software — it’s a competitive tool when backed by real engineering experience.

Whether you need help with:

Design optimisation

Drawings for manufacture

Assemblies and interference analysis

Fit-out design workflows

Investing in the right contractor doesn’t just fill a gap — it elevates your entire process.

👉 Explore Hamilton By Design’s SolidWorks services now.