Why You Should Engage SolidWorks Contractors for Engineering Success

In today’s competitive engineering landscape, turning ideas into reality quickly and accurately isn’t just a bonus — it’s a necessity. Whether you're refining a prototype, producing detailed manufacturing documentation, or preparing models for fabrication, the right CAD expertise can make all the difference.

That’s where SolidWorks contractors step in.

But not all contractors are the same and getting engineering outcomes you can trust requires more than just clicking buttons — you need experience, discipline, and a partner who understands both design and engineering.

What Makes SolidWorks So Valuable?

SolidWorks is one of the world’s most widely adopted 3D CAD platforms — and for good reason:

Intuitive interface and powerful modelling tools

Parametric design that lets you make changes quickly and confidently

Built-in analysis and drawing generation tools

Seamless compatibility with manufacturing and fabrication workflows

But software alone doesn’t guarantee results.

You need someone who knows how to apply SolidWorks to real engineering problems, not just create pretty pictures.

Why You Might Need a SolidWorks Contractor

Many businesses find themselves in one of these situations:

✅ Tight Project Deadlines

Internal teams are overloaded. You need quality output now, without sacrificing accuracy.

✅ Complex Geometry or New Challenges

Your in-house team hasn’t tackled this type of design before.

✅ Lack of Detailed Engineering Documentation

Good design isn’t just geometry — it’s drawings, tolerances, assembly references, and release notes.

✅ Need for Manufacturing or Fabrication Support

From CNC machining to sheet metal folding, your CAD model needs to behave correctly in the real world.

In all of these cases, a SolidWorks contractor with engineering experience becomes a strategic advantage.

More Than Just CAD — We Engineer Solutions

At its core, SolidWorks is a tool. What makes it powerful is who’s using it and how well they understand engineering intent.

A quality SolidWorks contractor should be able to deliver:

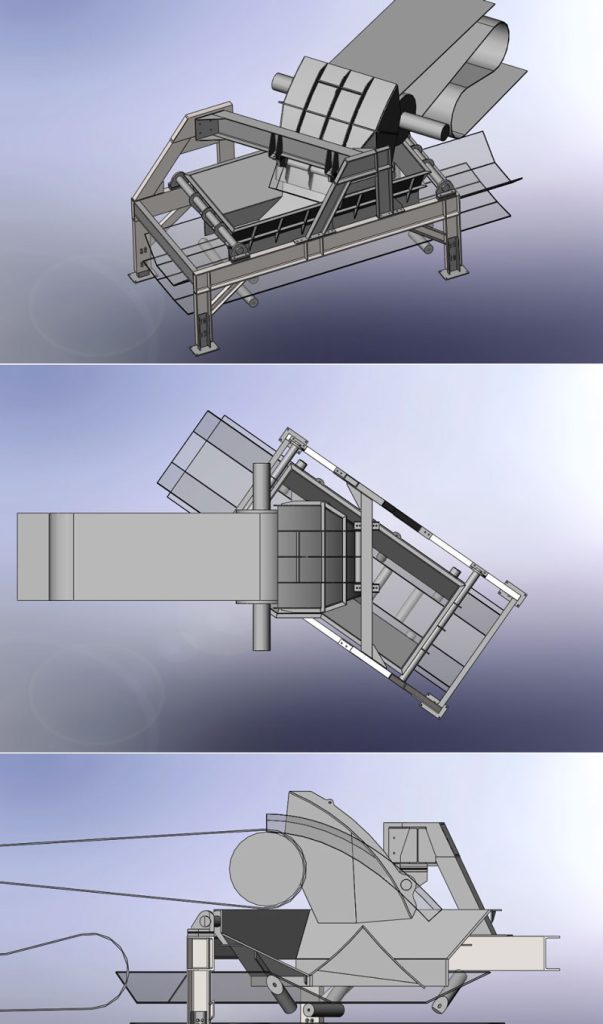

Product and machine design

Assembly modelling and interference checking

Sheet metal unfolding and DXF output

Detail drawings with tolerancing and annotations

Design for manufacturing (DFM) guidance

Revision control and documentation

This isn’t just “draughting” — it’s engineering.

When You Outsource CAD Work, Make It Worthwhile

Outsourcing your SolidWorks needs should elevate your team, not complicate your workflow.

A great contractor will:

✔ Work in your environment and standards

✔ Produce files that slot straight into your PLM/PDM

✔ Communicate clearly with your engineers

✔ Eliminate ambiguity in design intent

✔ Reduce errors, rework and ambiguity

Your engineering output shouldn’t just look good — it should function right the first time.

Trusted SolidWorks Expertise at Hamilton By Design

If you’re looking for more than just somebody “who knows SolidWorks,” look for someone who knows engineering and manufacturing — because that’s the combination that actually delivers results.

At Hamilton By Design, we specialise in SolidWorks engineering services that help companies:

📌 Bring products and machines from concept to production

📌 Optimise geometry for performance and manufacturability

📌 Deliver complete fabrication documentation

📌 Support revisions, assemblies, and integration with fabrication workflows

Whether you need short-term contract support or ongoing CAD engineering expertise, our team can step in seamlessly.

Want Better Results from Your CAD Work?

If you’ve been thinking:

“We need help with SolidWorks modelling”

“Our drawings aren’t detailed enough”

“We need someone who ‘gets’ engineering outcomes”

“We want to release designs faster and with fewer errors”

Then don’t settle for general CAD help — work with engineering professionals.

👉 Learn more about our SolidWorks engineering services here:

https://www.hamiltonbydesign.com.au/home/engineering-services/solidworks/

Let’s turn your ideas into engineered reality — faster, smarter, and with less headache.

Bottom Line

SolidWorks isn’t just software — it’s a competitive tool when backed by real engineering experience.

Whether you need help with:

Design optimisation

Drawings for manufacture

Assemblies and interference analysis

Fit-out design workflows

Investing in the right contractor doesn’t just fill a gap — it elevates your entire process.

👉 Explore Hamilton By Design’s SolidWorks services now.